Design & CNC Programming

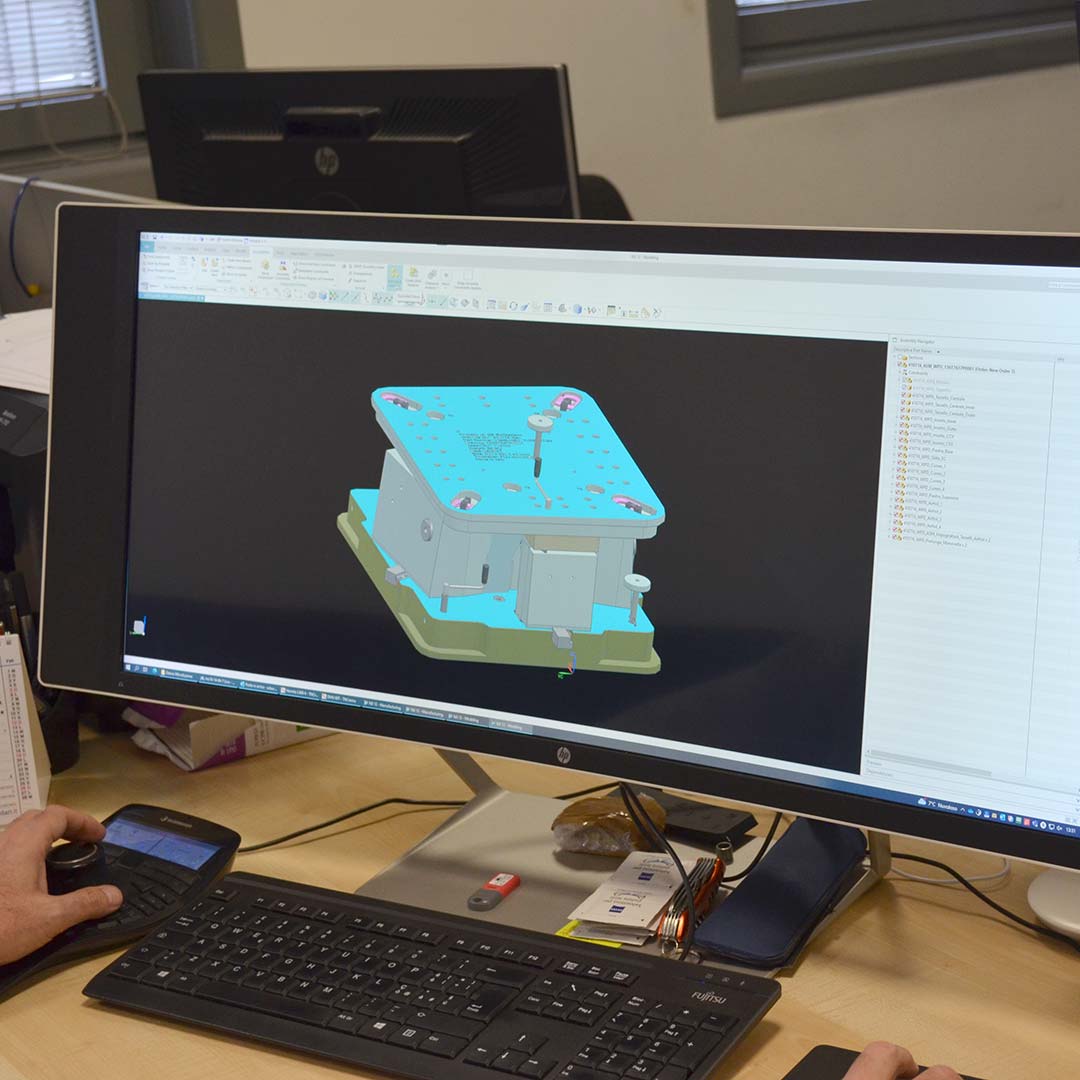

We receive from our client the casting to be carried out through the 3D model. Our engineering department begins to design the tooling, using the most advanced modelling software systems.

Once the product design is complete, the programming of the machine tools for milling is carried out through the CAD/CAM softwares.

MACHINING & FINISHING

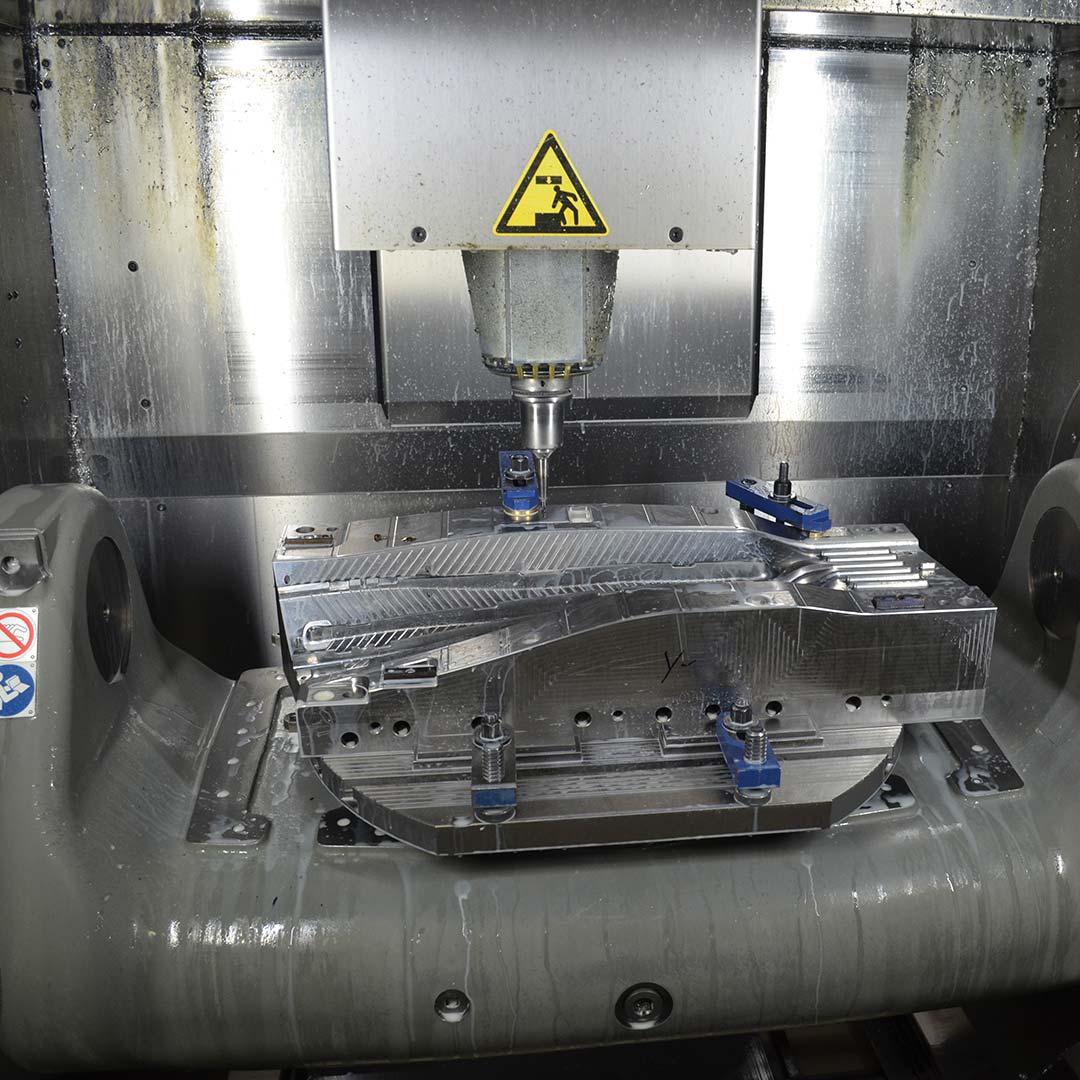

Thanks to our modern 3 and 5 axis milling centres, we create the casting and all the specific components for the product construction. For certain types of applications wire EDM technology is also used.

ASSEMBLY & TESTING

Once the processing of all components is finished, they are assembled. The assembly is performed with the utmost care and dedication typical of our handicraft vocation.

In case of request, markings are applied via laser system or engraved on the exterior of the product.

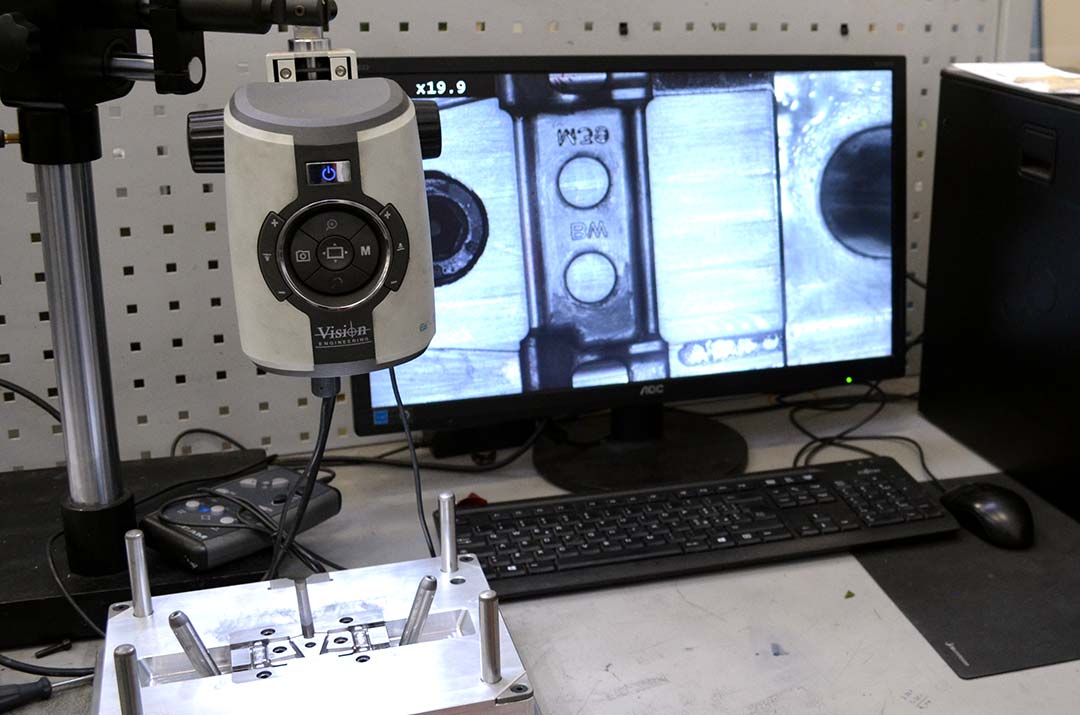

The product is finally checked with certified metrological systems, tested and then sent to our client.

On every casting, gauge or equipment changes and/or upkeep may be regularly carried out, so we can address client needs after the first or frequent uses.